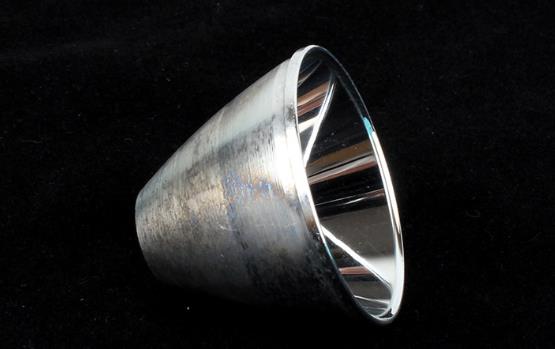

Normally, the light energy from the light source will radiate in a 360° direction. In order to effectively utilize the limited light energy, the lamp can control the illumination distance and illumination area of the main light spot through the light reflector. Reflective cup is a reflector that uses COB as the light source and needs distant lighting. It is usually cup type, commonly known as reflective cup

Reflective cup materials and advantages and disadvantages

Reflectior can be metal reflective cup and Plastic Reflector, the main advantages and disadvantages are shown in the following table:

|

Material |

Cost |

Optical Accuracy |

Temperature Resistance |

Heat Dissipation |

Deformation Resistance |

Conformity |

|

Metal |

Low |

Low |

High |

Good |

Low |

Low |

|

Plastic |

High |

High |

Middle |

Middle |

High |

High |

1, Metal Refletor: stamping, polishing process to complete, deformation memory, the advantages of low cost, temperature resistance, often used in low-grade lighting requirements of lamps and lanterns.

2. Plastic reflector: a demold completion, high optical accuracy, invisible memory, moderate cost, often used in the temperature is not high in high-grade lighting requirements of lamps and lanterns.

Difference of reflective rate:

The efficiency of the coating layer reflecting visible light. Vacuum plating of muon is the highest, vacuum plating of aluminum is the second, anodic oxidation is the lowest.

1, Vacuum aluminum plating: applied to temperature resistant plastic and metal reflective cup. Reflective rate is high, is the main coating process of automobiles and most of the high-end lamps and lanterns. There are two kinds of vacuum aluminum plating treatment, one is UV, can pass the salt spray test, the surface aluminum plating is not easy to fall off, measured reflectance of 89%. One is not UV. Surface aluminum plating may take a year or two to fall off, not suitable for use in coastal cities. The measured reflectance is 93%.

2, Anodic oxidation: applied to metal reflective cup. The effective reflective rate is less than half of vacuum aluminum plating. The advantage is not afraid of ultraviolet, infrared damage, and even can be cleaned with water.

3, For export enterprises, plastic cup can pass the safety regulations, aluminum cup can not pass the safety regulations.

4. Because the consistency of aluminum cups is low, if you make 100PCS of products, the spots may be different from each other. Because the plastic cups are made by one-time injection molding, the consistency is high. The light pattern is perfect.

5. The reflectance of aluminum cup is relatively low, and the reflectance of vacuum aluminum plating is up to 70%. The cost of light savings is enough to pay for the difference between plastic and aluminum cups, and if the wattage of the lamps is larger, the R&D costs can be reduced to a minimum.

6, The appearance of plastic reflector is more beautiful than metal reflector, High-end products.

Post time: Aug-10-2022