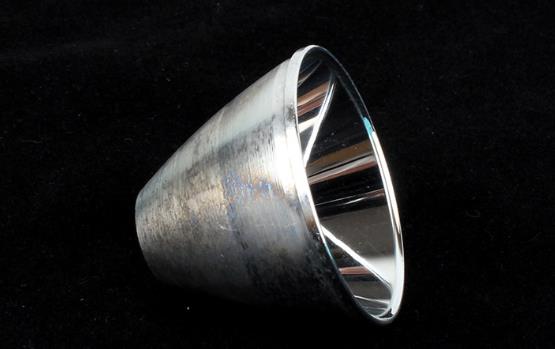

Ngokuqhelekileyo, amandla okukhanya avela kumthombo wokukhanya aya kukhanya kwicala le-360 °.Ukuze kusetyenziswe ngokukuko amandla okukhanya alinganiselweyo, isibane sinokulawula umgama wokukhanya kunye nommandla wokukhanyisa wendawo yokukhanya engundoqo ngesibonisi sokukhanya.Ikomityi ebonakalisayo sisibonisi esisebenzisa iCOB njengomthombo wokukhanya kwaye ifuna ukukhanya okude.Ngokuqhelekileyo luhlobo lwekomityi, eyaziwa ngokuba yikomityi ebonakalisayo

Izixhobo zekomityi ezibonakalisayo kunye neenzuzo kunye nokungalunganga

I-Reflector ingaba yindebe yentsimbi ebonakalisayo kunyeIReflector yePlastiki,iingenelo eziphambili kunye nezingeloncedo ziboniswe kolu luhlu lulandelayo:

| Izinto eziphathekayo | Iindleko | Ukuchaneka kwamehlo | Ukumelana nobushushu | Ukutshatyalaliswa kobushushu | Ukunyangwa kweDeformation | Ukuhambelana |

| Isinyithi | Phantsi | Phantsi | Phezulu | Kulungile | Phantsi | Phantsi |

| Iplastiki | Phezulu | Phezulu | Phakathi | Phakathi | Phezulu | Phezulu |

I-1, i-Metal Refletor: isitampu, inkqubo yokupolisha ukugqiba, imemori yokuguqulwa, inzuzo yexabiso eliphantsi, ukumelana nobushushu, ehlala isetyenziswa kwiimfuno zokukhanya eziphantsi kwezibane kunye nezibane.

2. Isibonisi sePlastiki: ukugqitywa kwe-demold, ukuchaneka okuphezulu kwe-optical, imemori engabonakaliyo, ixabiso elilinganisiweyo, elihlala lisetyenziswa kwiqondo lokushisa alikho phezulu kwiimfuno zokukhanyisa izibane kunye nezibane.

Umahluko wereyithi yokubonakalisa:

Ukusebenza komgangatho wokugquma obonisa ukukhanya okubonakalayo.I-vacuum plating ye-muon yeyona iphezulu, i-vacuum plating ye-aluminiyam yeyesibini, i-anodic oxidation yeyona iphantsi.

I-1, i-aluminiyam yokucoca i-aluminiyam: ifakwe kwiplastiki ekwazi ukumelana nobushushu kunye nekomityi yentsimbi ebonakalisayo.Izinga lokuzibonakalisa liphezulu, yeyona nkqubo iphambili yokugquma iimoto kunye noninzi lwezibane eziphezulu kunye nezibane.Kukho iindidi ezimbini zokucoca i-aluminiyam yokucoca i-vacuum, enye yi-UV, inokuluphumelela uvavanyo lwesitshizi setyuwa, i-aluminiyam yomgangatho ongaphezulu ayilulanga ukuwa, ukubonakaliswa kwe-89%.Enye ayiyo UV.Ukubekwa kwealuminiyam engaphezulu kunokuthatha unyaka okanye emibini ukuwa, ayifanelekanga ukusetyenziswa kwizixeko eziselunxwemeni.Ukubonakaliswa okulinganiselweyo ngama-93%.

I-2, i-Anodic oxidation: isetyenziswe kwikomityi yentsimbi ebonakalisayo.Ireyithi esebenzayo yokubonakalisa ingaphantsi kwesiqingatha se-vacuum plating ye-aluminiyam.Inzuzo ayiloyiki i-ultraviolet, umonakalo we-infrared, kwaye inokucocwa namanzi.

I-3, kumashishini athumela ngaphandle, indebe yeplastiki inokudlula imimiselo yokhuseleko, indebe ye-aluminium ayikwazi ukudlula imimiselo yokhuseleko.

4. Ngenxa yokuba ukuhambelana kweekomityi ze-aluminium kuphantsi, ukuba wenza i-100PCS yeemveliso, amabala anokuthi ahluke omnye komnye.Ngenxa yokuba iikomityi zeplastiki zenziwe ngokubumba isitofu sexesha elinye, ukuhambelana kuphezulu.Ipateni yokukhanya ilungile.

5. Ukubonakaliswa kwekomityi ye-aluminium iphantsi kakhulu, kwaye i-reflection ye-vacuum aluminium plating ifikelela kwi-70%.Iindleko zokulondolozwa kokukhanya zanele ukuhlawula umahluko phakathi kweplastiki kunye neekomityi ze-aluminium, kwaye ukuba umbane wezibane zikhulu, iindleko ze-R & D zingancitshiswa zibe zincinci.

I-6, Imbonakalo yeplastiki ebonisa iplastiki ihle kakhulu kunomfanekiso wesinyithi, iimveliso eziphezulu.

Ixesha lokuposa: Aug-10-2022